Non Destructive Testing Services

Non Destructive Testing refers to an array of techniques and processes to gain an understanding of the properties and qualities of a material without causing any damage to or affecting the serviceability of said material. NDT is often used to inspect serviceable materials for discontinuities and defects that may have an impact on their performance, such as impurities, voids, cracks and issues stemming from defective welding. NDT is an absolutely essential process for many different industries and sectors including aerospace, infrastructure, construction, manufacturing, energy & transportation; as it is incredibly important that material components and equipment are all highly functional and adhere strictly to all safety policies to reduce risk of harm or death.

Weld Qual Services offer a comprehensive range of non destructive testing services to ensure that any fabrication work has been thoroughly tested and is held to the highest possible standard whilst complying with all relevant procedures and safety regulations.

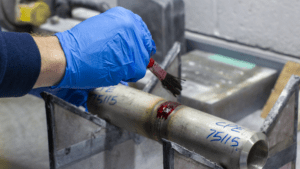

Dye Penetrant Inspection

Dye Penetrant Testing (PT or DPI) is a type of NDT using a dye penetrant to inspect for surface breaking faults in non-porous materials such as metals, plastics and ceramics. This form of testing is often applied to non-ferrous materials. In PT weld inspections, a liquid penetrant is applied to a surface and left to stand for a period of time, before being cleaned away, where a developer is applied to the surface to draw the penetrant out of any flaws in the material, which will make the flaw show up in an obvious way. It is often used to detect surface discontinuities and defects in forging, casting and welding such as surface porosity, hairline cracks and fractures, fatigue damage and leaks. The penetrant used is normally a brightly coloured dye with high wetting capabilities, often fluorescent dye is used.

Dye Penetration Testing has two major advantages over other forms of NDT Weld Inspection, namely its comparative speed and relatively low cost. A Dye Pen NDT Technician is able to carry out dye penetrant testing both onsite and offsite with relative ease. However, some disadvantages are that it can only detect surface flaws, and needs to be carried out on a smooth, flat surface by a qualified and experienced technician like those at Weld Qual Services to fully be effective and not come up with false indications.

Magnetic Particle Inspection

Magnetic Particle Non Destructive Testing (MT or MPI), is a form of non destructive testing used primarily to identify defects on the surface of ferromagnetic materials by running a magnetic current through said materials. It can sometimes also be used to detect defects just under the surface of the material, though it is not effective when attempting to map out the internal structure of welds and materials. Some of the defects that can be detected during an MPI test include cracks, cold lap, pores and incorrect or insufficient sidewall fusion in welds. It is a widely used form of non destructive testing that is very useful in detecting surface discontinuities that are too small to be seen by the naked eye during a visual welding inspection, or would require microscopic enhancement to be seen.

The first step when conducting an MPI NDT test is where an NDT technician will magnetise the material that they need to inspect. This can be done either by direct or indirect magnetisation. Direct magnetisation involves an electromagnetic current being passed directly through the test specimen, forming a magnetic field within the material. Indirect magnetisation is where no electromagnetic current is passed directly through the test object, but a magnetic field is applied from an outside source. If the test object is sound, without any defects or surface discontinuities, the magnetic field applied to the object will transfer throughout the material without interruption. However, any cracks or defects will cause the magnetic field to be interrupted, creating what is known as a flux leakage field around the location of the defective area. After the material has been thoroughly magnetised and these leakage fields have been created, an NDT technician will spread magnetic particles over the test piece. These particles will then gravitate to the areas where the leakage field is present, thus alerting the NDT technician to the crack or defect.

Ultrasonic Inspection

Ultrasonic Non Destructive Testing (UT) is a form of NDT that uses ultrasonic waves to test for flaws both internal and external in a material or object. High frequency sound waves are passed through the material which are then picked up to map out the structure of said material, including any flaws or discontinuities. Ultrasonic testing is an ideal NDT method as it can test and map out the internal structure of an object rather than just find surface defects, and causes no damage to said object. UT non destructive testing has many applications in the welding and fabrications industry, one of the most common is thickness testing, which is used to detect the thickness of an object when assessing pipework for corrosion. Alongside this, periodic inspections can take place to test for corrosion in an object as well as the growth of known flaws.

There are many advantages for using the ultrasonic non destructive testing method. These include its high penetration power, meaning it is able to detect flaws deep within an object rather than just on the surface, along with its high sensitivity, which allows it to detect very small flaws in said material. It can also be used to test an object when only one side of the object is accessible to the tester, and is often a lot more accurate than other non destructive testing methods. Results are available immediately, making it one of the fastest non destructive testing techniques around, and it is non-hazardous to humans and the environment.

GET IN TOUCH

If you’re interested in any of the services we offer or would like to find out more please submit the enquiry form below and a member of our friebdly team will be in touch.